The True Cost of Custom Machinery

Its been about two years since I made Mastering the Machine available on this website. For those who haven’t read it, it is a short e-book describing the process of concepting, quoting, building and installing custom machinery.

I have also mentioned in several posts the process by which machine builders go about quoting jobs. Of course machine builders want to make as much profit as the market will bear; they certainly don’t want to lose money. At the same time they are in competition with other machine builders and need to stay competitive. In a previous post I described the format of the typical spreadsheet machine builders use when quoting a machine or system.

“The first place in a machine’s design cycle where Excel is useful is the quote itself. Larger machine builders usually semi-automate the quote process by creating a list of parts for the proposed system with component pricing. The more items that can be accounted for on the front end, the more accurate the quote will be. Major components are easy to account for. PLCs, HMIs, enclosures, actuators, valves, framing and structural components, purchased subassemblies and test equipment make up a significant portion of the hardware list. Smaller items like terminal blocks, fasteners and small mechanical components can be estimated by category.

By having an Excel template with all of these categories listed one can ensure that nothing major is left out. Categories can also have labor estimating tools built into the spreadsheet. Each type of component takes a certain amount of labor to install or fabricate, and a lot of time can be saved by pre-assigning a number of hours by discipline; i.e. 0.5 hours per sensor for electrical design, 0.5 hours per input point for programming, 0.25 hours for each machining operation (cut, drill, etc.). As a component is entered, each of these categories can be populated automatically.”

In a typical quote spreadsheet hours are estimated by section, with input from engineering, fabrication/machining and administrative/project management disciplines. Hopefully estimates are based on previous jobs, but when data is not readily available this is the first place where “padding” occurs. This is addition to the hourly rates being rounded up for each discipline.

Purchased commercial items are also listed in the spreadsheet, but some generic items like sensors, valves, fasteners. motors and the like are often simply totaled and a representative amount is assigned. This holds for most small components. Because there is a good chance of error the number of items is often rounded up. Here is another area of “padding”.

A category for “unidentified” is often included as a percentage and added to the subtotal. While the intent of this category may be to compensate for items that are left out, this usually duplicates the padding within the other categories. The unidentified category is typically 2-3% of purchased and fabricated parts.

All of the subcategories are usually then each assigned different margins to provide for a profit. Vendor components may be marked up 15-18%, fabricated components up to 35%. Labor costs may be marked up also or the margin can be built into the hourly rates for each discipline.

While there is a real risk associated with the estimation of costs for a project, most machine builders meet their goals on 90%+ of quoted projects. Of course there is the occasional bad apple that can eat up the profits of several successful projects, but overall an experienced company exceeds expectations on most proposals.

One of the biggest problems for machine builders is the cyclic nature of the business. A company needs to be staffed for the amount of work being done. Even with layoffs and use of contract labor, a core of talented, experienced engineers, project managers and technicians need to be kept on staff even when the workload is light. This along with facilities and administrative staff represent overhead spread between all projects.

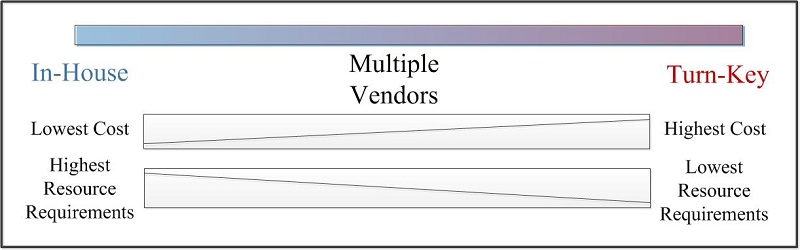

This is where the diagram at the top of this post comes in. When purchasing a turn-key project from a vendor the costs are easily 50-100% or more higher than if you were to try and do the project in-house. This is without even considering the possibility of using repurposed/used equipment. Of course most manufacturers don’t have the capability of doing this on their own due to needing specialized talent and tools, but there is still a wide range of methods between the two extremes of the diagram.

If you haven’t downloaded Mastering the Machine yet, I would encourage you to do so. Though I do ask for your e-mail address, I don’t send out unsolicited e-mails or share information with others. While I originally intended to write e-mails at least quarterly, it turns out that I am too lazy and have not even been keeping up with my “thanks for subscribing” e-mails; the last one I sent was over a year ago. And you can always unsubscribe.

As far as why I wrote Mastering the Machine (and this post) in the first place, I spend an ever increasing percentage of my time helping customers put together systems at a lower cost than if they were to go turn-key with a machine builder. This will be covered in more detail at a later date, but until then, feel free to contact me if you would like to discuss this further.