Kaizen

A major element of Lean methodology is Kaizen, or “improvement”. The term can refer to a continuous process or to a planned improvement event concentrating on a specific target.

A major element of Lean methodology is Kaizen, or “improvement”. The term can refer to a continuous process or to a planned improvement event concentrating on a specific target.

From the Industrial Automation: Hands On manuscript:

Continuous improvement, or Kaizen, is a major element of the TQM system and is used in manufacturing, engineering and business management. It involves all employees of a company, from the CEO to production workers. By improving and standardizing processes, waste is eliminated, achieving the goals of lean methodology.

Kaizen is a daily process that teaches employees to apply a scientific method to the identification and elimination of waste. It can be applied individually, but often small groups are formed to look at specific applications or work areas. The group may be guided by a line supervisor but may also be assisted or led by people trained in Six Sigma techniques.

Kaizen events are often organized as a week-long activity to address a specific issue. They are sometimes referred to as a “Kaizen Blitz.” They are generally very limited in scope and involve all personnel involved in the process. Results from a kaizen event are often used in later events after careful evaluation.

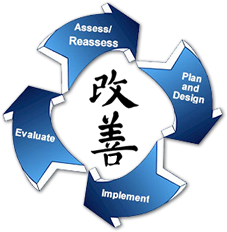

A kaizen cycle can be divided into several steps. The first is to standardize an operation or its activities – in other words, ensuring that a system is in place in the beginning. The next step is to measure the operation using whatever measurement is appropriate. Examples include cycle time, waste material, in-process inventory or defective parts. These measurements are then compared to the design requirements of the operation. Innovations and improvements can then be applied to the process and, hopefully, improve productivity. In turn, the results of this cycle become the new standard, which is used as the basis for the next kaizen, and the cycle repeats.

Another name for this cycle is PDCA – an acronym for “Plan-Do-Check-Act” or “Plan-Do-Check-Adjust.” The planning stage is used to establish the objectives and processes necessary to achieve the desired results. Doing involves implementing the plan, executing the process or making the product. Data collection about the process is also performed during this step. The checking stage studies the results gathered during the previous step. Comparing the results to what was expected is made easier by charting the data and making it easier to spot trends. The acting or adjusting stage is used to apply corrective actions to the process. The PDCA cycle predates kaizen by many years and has its roots in the origination of the scientific method hundreds of years ago.

I had planned on writing a post on future trends in automation but ended up staying out very late last night playing a Halloween gig with my band.  So yes, this week I decided to “phone it in”. Next week I plan to discuss the future of automation inspired by Jim Pinto’s “Technology Megatrends” article.

So yes, this week I decided to “phone it in”. Next week I plan to discuss the future of automation inspired by Jim Pinto’s “Technology Megatrends” article.

Boo.