More on Specifications

A couple of months ago I wrote a post on cross referencing; that is, finding a replacement for an existing component. In this post I’d like to elaborate a little bit on specifying components in general.

When replacing a component you have a place to start. Using the specifications from the existing equipment it is fairly straightforward to find something similar from another manufacturer. These are some of the things to consider that I listed in the last post:

1. Electrical Interface/Signal Compatibility: AC/DC, voltage/frequency, PNP/NPN, 0-10v/4-20mA and physical cable connections. Communications drivers and cabling between devices.

2. Physical Compatibility: Mounting method and space constraints, environmental issues such as washdown and temperature, special purpose factors such as explosion proof or intrinsic safety, physical interfacing with other components such as couplings.

3. Support Compatibility: Is the item easily obtained if it fails, are there local people who can help me if the software needs to be modified? Are my own people experienced with the item or platform or can they get training?

When specifying new components the range of choices may be even wider. For instance, maybe you have always used a 0-10v pressure transmitter for measuring tank levels; if you have the flexibility to use a 4-20mA signal, this allows you to use Hart protocol for setting parameters. Different forms of network I/O devices may also be used, maybe it’s time to ditch the old DeviceNet network and move to Ethernet I/P or Profibus, depending on your controls platform.

There are also many third party vendors that make components that work with your platform. Prosoft is a well known vendor for Allen-Bradley cards, while companies like Beckhoff make some nice distributed I/O devices that work in various systems.

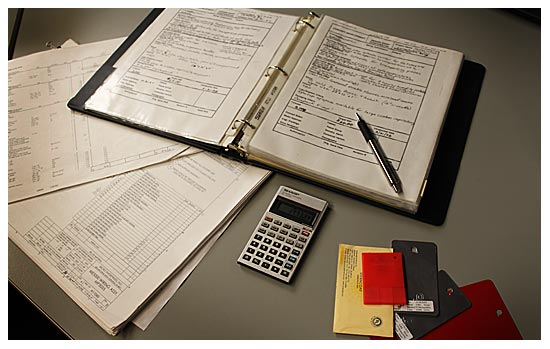

One resource that is often underutilized is local vendors. Technical salespeople have often been to facilities all over the area and have seen how other people use their products. They are usually up to speed on the latest and greatest, though sometimes they can be so eager to sell their “new” products that they overlook the tried and true. That’s where careful attention to the specifications can pay off. Typically I make a folder full of “cut sheets” during design so that I can evaluate products against each other.