LVDTs

One of the first applications I wrote about on this blog back in January 2011 was a Rocker Arm Cover gauge that used a number of LVDTs to calculate a plane and its intercept points. In that blog I concentrated more on the application than on the technology behind it, so today I am going to cover the LVDTs themselves.

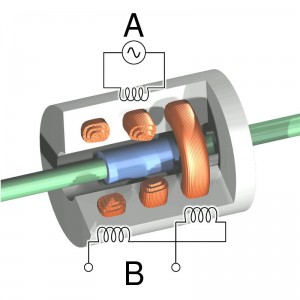

Linear Variable Differential Transducers, or LVDTs are a type of electrical transformer used for measuring linear displacement. The transformer has three solenoidal coils placed end-to-end around a tube. The center coil is the primary, and the two outer coils are the secondaries. A cylindrical ferromagnetic core, attached to the object whose position is to be measured, slides along the axis of the tube.

An alternating current is driven through the primary, causing a voltage to be induced in each secondary proportional to its mutual inductance with the primary. The frequency is usually in the range of 1 to 10 kHz.

As the core moves, these mutual inductances change, causing the voltages induced in the secondaries to change. The coils are connected in reverse series, so that the output voltage is the difference (hence “differential”) between the two secondary voltages. When the core is in its central position, equidistant between the two secondaries, equal but opposite voltages are induced in these two coils, so the output voltage is zero.

When the core is displaced in one direction, the voltage in one coil increases as the other decreases. This causes the output voltage to increase from zero to a maximum. The output voltage is in phase with the primary voltage. When the core moves in the other direction, the output voltage also increases from zero to a maximum, but its phase is opposite to that of the primary. The magnitude of the output voltage is proportional to the distance moved by the core (up to its limit of travel), which is why the device is described as “linear”. The phase of the voltage indicates the direction of the displacement.

Because the sliding core does not touch the inside of the tube, it can move without friction, making the LVDT a highly reliable device. The absence of any sliding or rotating contacts allows the LVDT to be completely sealed against the environment.

LVDTs are commonly used for position feedback in servomechanisms, and for automated measurement in machine tools and many other industrial and scientific applications.

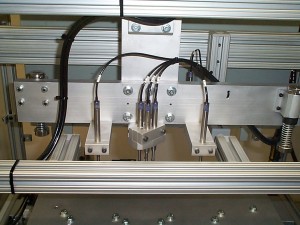

This is a close up view of the LVDTs used in the Rocker Cover Gauge application. Because of the recalculation of the intercepts during every measurement, this machine was very easy to calibrate as long as none of the sensors were moved.

This is such a great resource that you are providing and you give it away free. I love seeing website that understands the value of providing a quality resource for free.

Regards

LVDT