Industrial Education Ch. 6: Summary

This series of posts discusses the current state of industrial education in the US and around the world. I will cover topics covering elementary through high school education (including the STEM programs), vocational/technical schools and colleges, independent for profit courses both online and in-person, and some of the resources that can be found on the internet.

*************************************

I had thought my post on universities would be the last in this series, but it turned out I had more thoughts on the subject, so I decided to summarize my findings and discussions.

A little more than six years ago I started transitioning from doing design and programming work for custom machinery to teaching PLC and HMI programming. At first it was mostly contract work for Automation Training, who I still teach for. I traveled around the country doing classes in factories and conference rooms, meeting a lot of technicians and engineers, and occasionally got to discuss their previous training. Of course since I teach a specific technical skill, that is mostly what I learned about.

After I started my own training facility I started getting more in touch with the local community, and also branched out into teaching some other subjects. Back in December when I decided to write this series of posts, I started interviewing people in my area about education overall, and more specifically how well it would prepare students for future jobs in technology. What I found was a bit depressing.

After WWII, when the US had the luxury of being able to devote more resources and thought to the education system, there were several changes that took place over time. Different states could try different things and figure out what worked and what didn’t. In addition to the “3 Rs”, Reading, ‘Riting and ‘Rithmetic, various new subjects started appearing in schools, from art to humanities, and of course more science and eventually technology. “Shop” classes would be instituted in junior high and high schools, including auto mechanics, machining, and even as on friend told me about his high school experience, “printing” shop. His high school in Iowa had five different types of hands on shop classes, including one for printing technology. This was in the 1960s, and his brother took these classes. He ended up working in the printing industry for over 40 years and eventually retired. So obviously classes like this were beneficial for many, especially kids that may have not had many other options besides farming.

In the 1990s it became well known that the US was falling behind other developed countries, and even some less developed ones, in science and math. The “STEM” (Science, Technology, Engineering, and Math) movement began, but then got watered down with other subjects as proponents of other subjects such as arts and writing felt that their subjects were losing funding to the STEM subjects. As mentioned in my previous posts, STEM became STEAM, then STREAM, and now in my opinion is simply a buzzword.

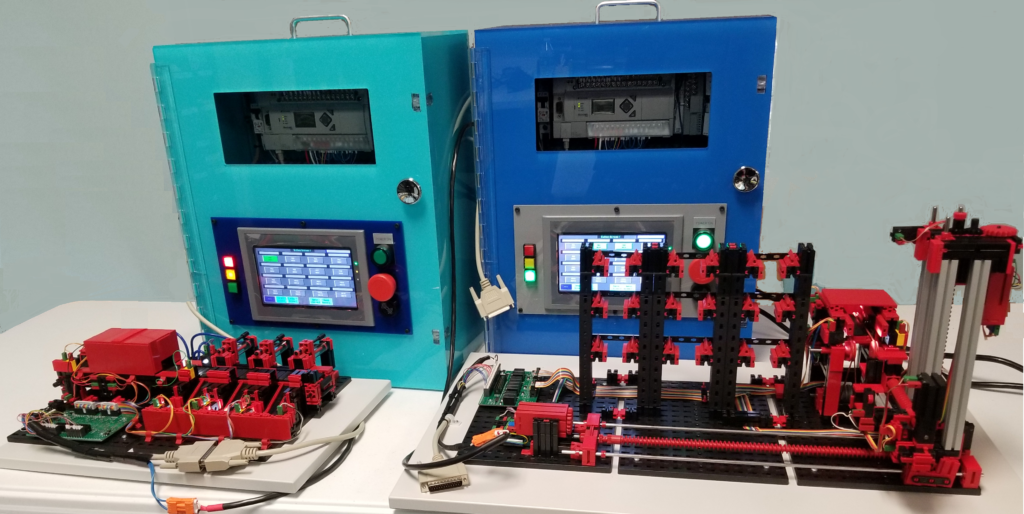

I’m sure the intent of the above image is to interest children in technology and STEM, but the fact is, it’s just another fun toy to children. There are a lot of toys around now that will “Blow your Mind”, along with cell phones, computers and cool websites. Yet elementary students may not know how to use a pair of scissors or create something from imagination.

When I called my local high school to offer the FREE services of my training facility (which has a lot of “cool toys” like pneumatics, machine vision, PLCs, even Arduino and Raspberry Pi microprocessors) to high school STEM programs, the STEM coordinator informed me that she was a biology teacher and that their STEM program was for biotechnology. I dug a bit deeper, asking if they had interest in the technology for checking soil moisture or humidity, I was informed that there was really no place for that at this school. She referred me to another school that she thought might have a mechanical STEM program, and that the neighboring city had a robotics STEM club. So in many schools a kid with interest in an engineering or technical path has no resources, despite the US being one of the richest countries in the world. Unless they can get a ride to somewhere far away.

Even there I made another interesting discovery, my local high school’s hours are 7:50-2:50, while the next closest high school’s hours are 8:45-3:45. I have heard that the reason for this is that the buses have to carry students from both schools, and there aren’t enough buses or enough drivers. Kids often don’t get home until after 5pm.

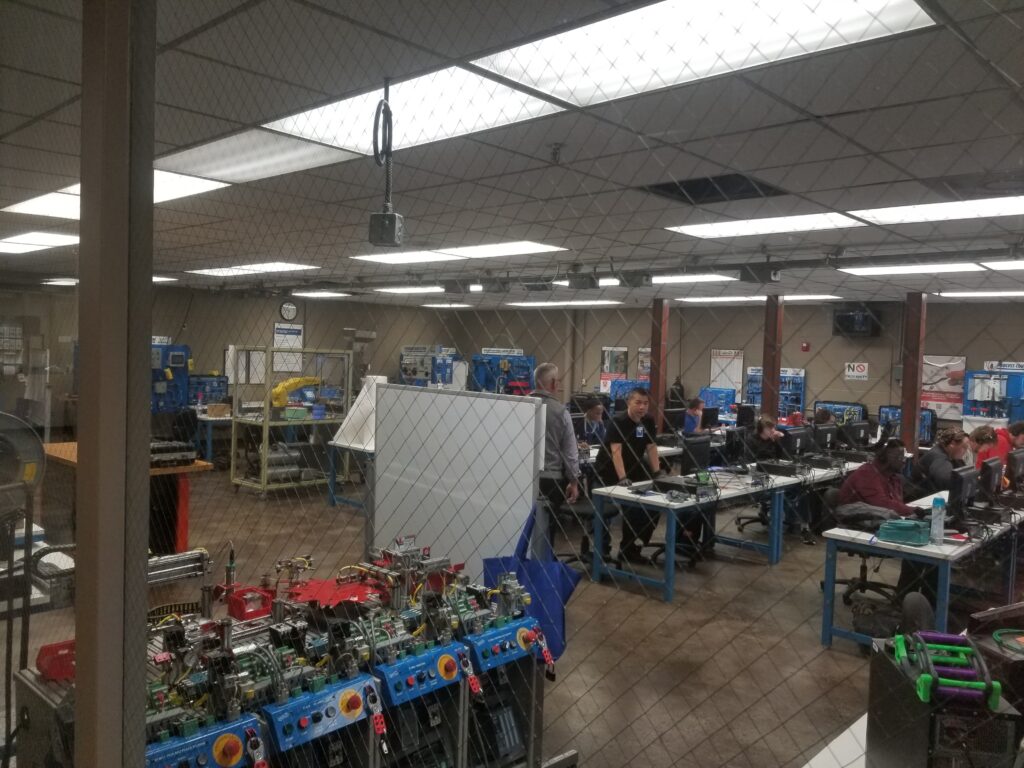

When it came to the vo-techs and junior colleges, I had an ulterior motive since I am hoping to get my products and curriculum into them. So I made my visit a combination sales call and fact-finding mission. As I already knew, these schools spend a lot of money on nice labequipment. Most of the industrial automation related trainers are made by a company called Amatrol. While they do a nice job with the hardware, it is quite expensive.

The picture above is a picture I took through the glass at my local technology school. As I mentioned in Ch.4, I had taught some of the instructors at another school here in the state where they had invested a lot of money in equipment. So when it came time to build my own lab equipment I went to Amatrol to see what they could do for me. Their quote was quite expensive from my perspective, and they couldn’t customize it for me. It also came with their training curriculum, which I read through, and while it might be appropriate for some very low level industrial classes, it was nowhere close to what I needed.

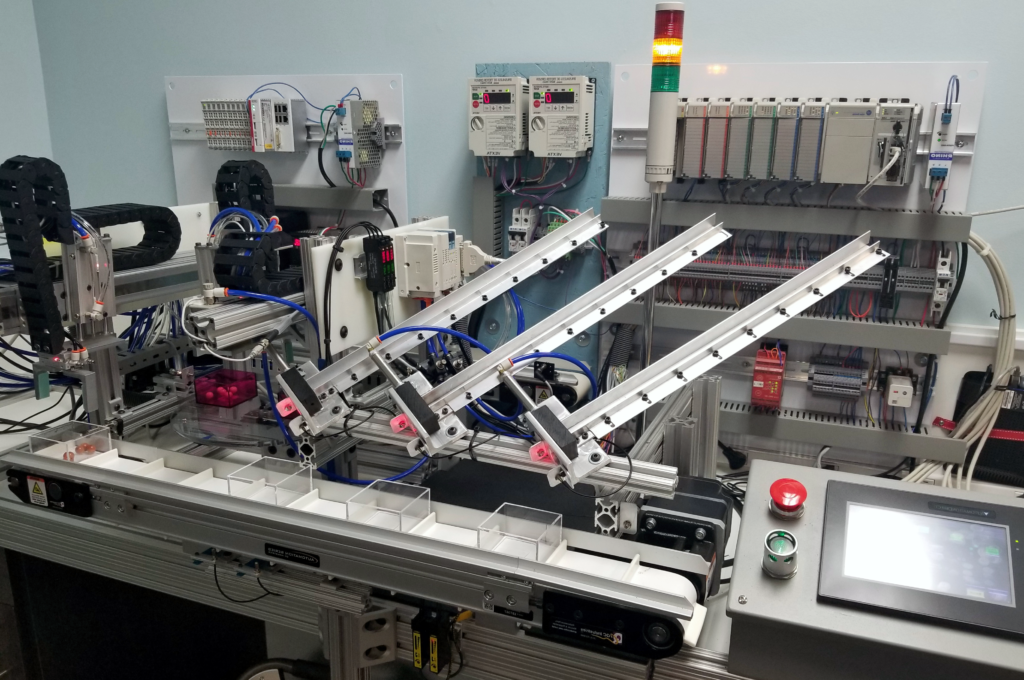

So I ended up building my own application. I used to build custom machinery out of extrusion, so I was able to build a pretty nice little trainer. It has since evolved a bit, and I occasionally use it for advanced training for a local engineering company. At the same time, it took a long time to build myself, and I have no urge to get back into the machine building business.

This evolved into a different project to come up with much less expensive options. These trainers are geared towards actually teaching students how to write a complete program, which is not what the community colleges teach. Community colleges and vo-tech schools need to be focused on the needs of the community, which is sort of a “lowest common denominator” approach. A friend I talked to last week said that about half of the kids in his tech school classes were young disinterested “punks” (his term, not mine) that had no idea what they wanted to do, but mom and dad would kick them out of the house if they didn’t go to school. This was the cheapest option.

Of course there are lots of exceptions, and some kids want and need more advanced training, which is where us independent companies come in. The problem there is that to afford an experienced teacher, software and good equipment the classes are much shorter in length. Again there is the economic aspect and also the lowest common denominator; classes have to meet the needs of industrial maintenance technicians, which again is more troubleshooting than creation.

So in summary despite all the talk about catching up other countries academics, we spend a lot of money on education, but don’t pay teachers much. Students are also distracted by a lot of other things and have a lot less discipline and focus than even a few decades ago.

I have kids of my own (though in their 30’s and no longer “kids”). Despite going to a middle of the road public school, they both went off to college and excelled, though not in industrial technical fields. The reason was that all the learning material was there, and my wife and I as parents were very involved in their lives and their education. But parents often leave the education entirely up to the schools, which is a huge mistake.

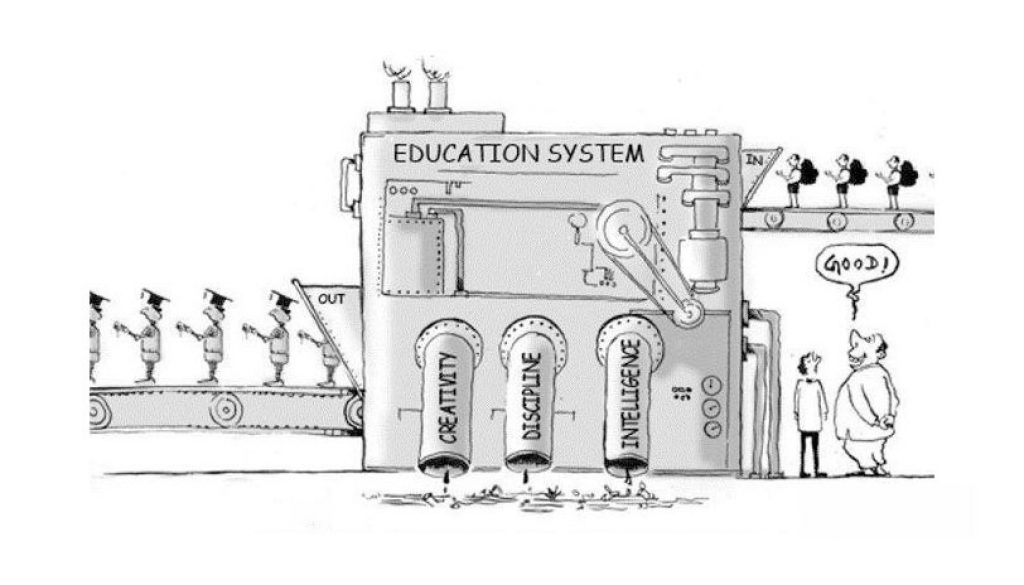

We are not the only country with this challenge, the picture at the top of this post came from an article from 2014 in India. The article said much of the same things that I have discovered.

This really is the final post of this series this time. Let me know what your experiences have been!