HMIs and Operator Interfaces

The acronym HMI is ofthen interchanged with the term MMI (Man-Machine Interface) or OIT (Operator Interface Terminal). The use of a touchscreen or computer monitor also implies the use of a GUI or Graphical User Interface. Prior to the use of screens with graphical capabilities buttons were often built into the operator inteface for numerical data entry and LCD or LED displays were used for text. With the improvement in graphical capability and touchscreen technology these older operator interfaces are not as prevalent today.

Computers are often used on the factory floor today both as operator interfaces and data storage. They are easily integrated into plant networks and are more industrially rugged than during the 20th century. Often much of the operating system can be disabled to streamline the memory usage or stripped down versions such as Windows CE are used. Manufacturers often use this as their runtime platform.

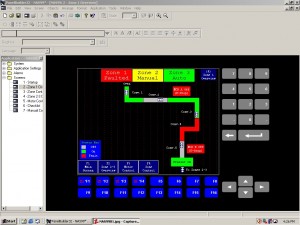

Programming software has also become much more user friendly along with the improvement in computer technology. Digitized images of the machine or its products are now easily integrated with the screens and moving graphics indicating machine operations are common.

With the continued improvements in hardware and software technology HMIs will only become more capable and less expensive.