Build your Own Enclosure

Back in November I posted an article about the PLC Trainer Kits that I had created for people to wire their own PLC. I mentioned that the plastic boxes I was using didn’t travel well, and that the one I had shipped to Massachusetts for Shawn Tierney had broken in shipping. I redesigned the enclosure as a build-it-yourself kit, making it sturdier and allowing it to be shipped flat, saving shipping costs and creating yet another project for people to work on.

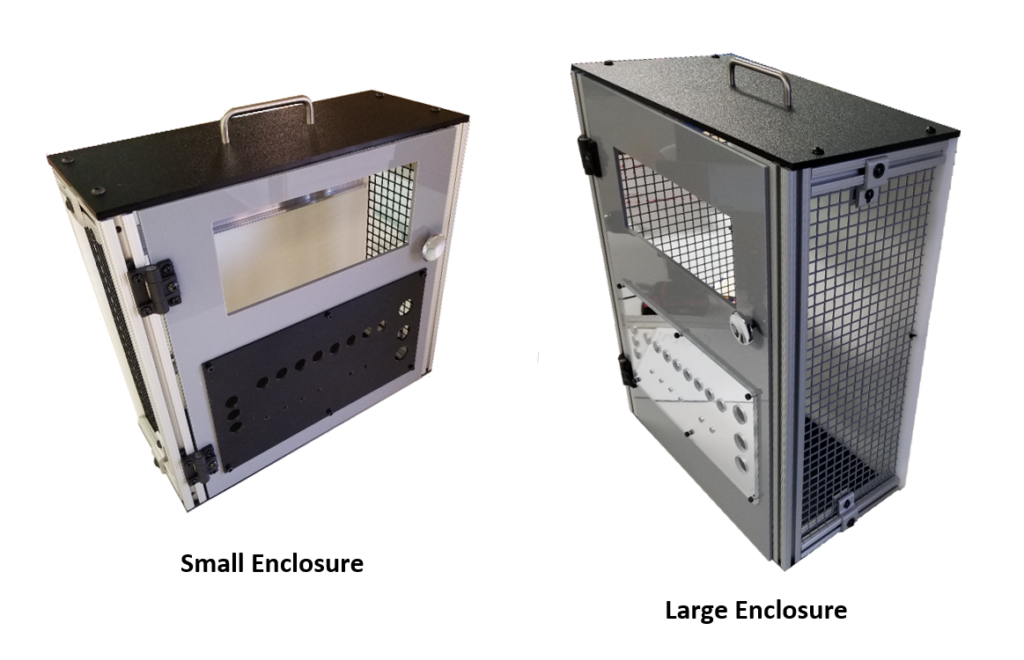

The enclosure has an extrusion frame and an ABS backplane that can be tapped to mount components on. The backplane is pre-tapped for mounting din-rail, but for larger rack-based PLCs I wanted to allow the user to place components as desired.

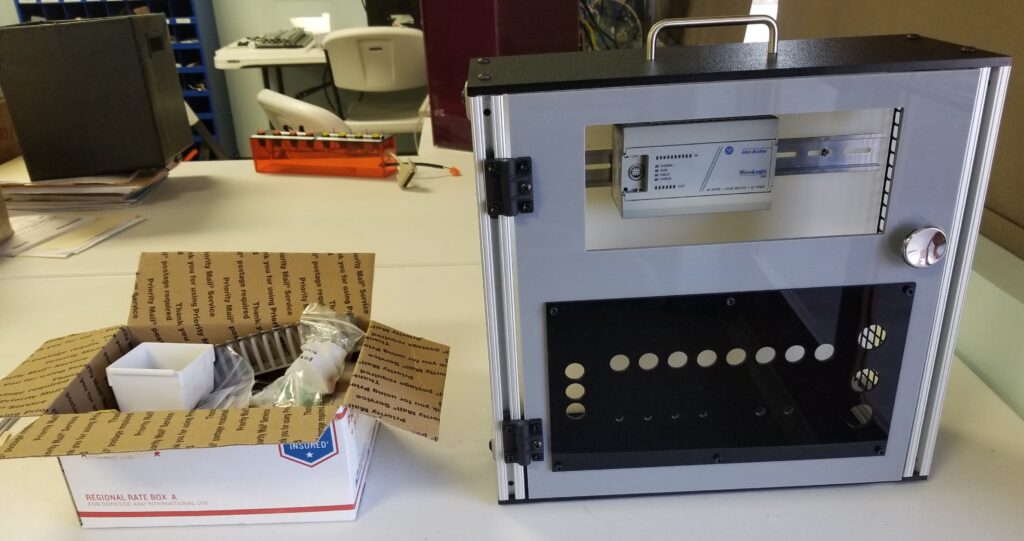

I am now writing the instructions for building the enclosure. I ordered enough components to build two small and two large enclosures and sent Shawn one of the small kits to replace the one that broke. I build the large kit for practice, and as I mentioned last week I am using it in my new machine vision lab. I just finished building the remaining smaller one (parts shown above) and will probably keep it as a demo.

I’d say it took me an hour or two to build the enclosure, but I took pictures of every step for the documentation. The picture above shows the two different sizes assembled.

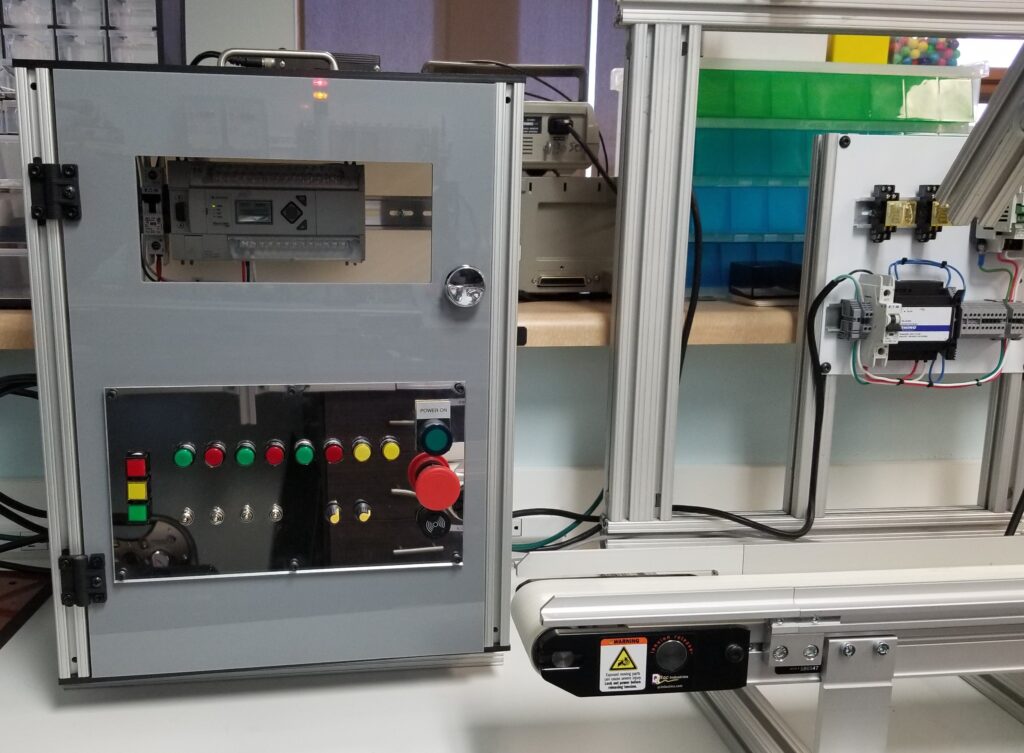

So now the enclosure and the kit with all the wiring components are kind of separate items. My thought is that some people may just want the enclosure box to mount other things in, such as valve banks or non-PLC automation components. As I mentioned, I used the larger enclosure for my machine vision lab.

This design has just kind of evolved out of necessity; I built my Fischertechnik simulation trainers for my own use and to sell as trainers, then the trainer kits evolved because Shawn mentioned people had asked him for a kit that people could put their own PLC in. Then the enclosure evolved because of shipping. Its turned into a pretty cool accessory, the mesh on the sides allows air hoses and cables to be routed without putting fittings in the sides, and as I mentioned its shipped flat so it takes up less space for storage.

What I don’t know is, will people buy it? Do you see a need for something like this? Have you ever seen a build it yourself enclosure for automation components? It is certainly not a NEMA box and won’t keep water out… but for trainers it costs a bit less than a metal enclosure and already has all the holes drilled for components… I eagerly await your comments…