Unitronics

Today’s post, as promised last week, is written by Ryan McCarthy, a reader of this blog. While I always offer to place a reciprocal link to the website of whoever contributes guest posts to this site, amazingly Ryan is neither currently a blogger nor does he work for Unitronics. One plug I will give him though; he lives in Florida and is looking for work in the controls and automation field, so if any of you can help out, hit me up and I will put you in contact. We have corresponded a bit and he seems like he would be a great hire or automation partner, plus he writes quite well! Ryan, you really should start a blog yourself. Anyway, since I don’t know much about the subject other than that it is a PLC with built-in HMI (or vice-versa), I’ll let Ryan take it from here.

****************************************

Unitronics is a younger company that started in 1989 and has since grown to be a more common name in the industry. Unitronics offers PLCs that are “All-in-One”, which means all their PLCs have a built-in HMI as well as communications. Based on my experience on other platforms, this really simplifies things. When I started out I had entire days spent getting a laptop set up to handle a project, from a communications software, an HMI software, perhaps two versions of a PLC platform when working to update a PLC. With Unitronics there are only three pieces of software total, the U90 Ladder, VisiLogic, or UniLogic.

The big upside of Unitronics is the very low cost of hardware. I/O modules are 100-300, whether discrete, analog, RTD and whatnot. Estimates I saw on their high-end processors that include the HMI are less than $1,500. However, depending on which platform you go with, the cost might be higher due to programming time. Their lower end runs in the few hundreds. Mind you, these still have touch screen displays around $400 included in that price. Development time is a bit higher in that environment, and there are several more constraints, however I’ve seen it have popularity with “copy-and-paste” applications for product lines.

I almost forgot this – they offer free support. Some of you might be thinking “free? Yeah you get what you pay for”. That may be true, but I’ve gotten to meet some of their technical support engineers and the guys are great! They have a forum on their website with both tech support and altruistic integrators helping answer questions. Personally, I’m a big fan of the company. They are strictly a hardware company and make no money on the software side.

You could look at their three-product series as tiers – low, middle, and high. The U90 series covers keyboard entry and text display type HMIs, current models being sold are the Jazz and M91, under 50 total I/O sort of range. Vision covers their base touchscreen models, the V130-V1210 and SAMBA processors, which have their varying HMI sizes, processing power, and memory. This covers projects up to 1000 I/O with snap-in expansions. UniStream covers their high-end product line, which comes with an improved ladder diagram and enhanced features all around. This line can expand to 2000 I/O.

Now that a general overview is covered I want to go into a little detail on each of those platforms – U90 Ladder, VisiLogic, and UniLogic.

U90 Ladder – The U90 ladder is for very simple inputs and displays. It is like VisiLogic except with the limitations of keyboard entry as opposed to touch screen, and strictly text display. As a result, the HMI and complexity of applications on this platform are limited. Going into detail about VisiLogic pretty well covers the logic functionalities of both the U90 Ladder and VisiLogic.

VisiLogic –

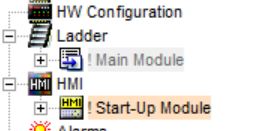

You would start by configuring your hardware, which is a very visual drag and drop process. This allows you to visualize exactly how you would build your snap in I/O and expansions on to the backplane. See the following for an example:

After configuring your hardware, you might setup your communications. The controller supports serial, TCP/IP, and OPLC communications. The ladder has a few drawbacks, it is an addressed (not tag-based) database without user-defined tags or add-on instructions, so you’ll be spending some time on your I/O upfront. There is a third-party simulator available for 30 euros to test your project and it’s strictly for certain VisiLogic configurations. Side note – I’ve heard it’s not so great (“sucks”) from an integrator, but I have no experience using it myself. You must connect every element in the ladder manually by placing them or connecting them with a line, it doesn’t do anything intuitively like most platforms. As long as you use the right communication protocol for your project, communications are nice and function blocked.

The HMI is nice, but different from the norm. Most applications I have made or seen involve a lot of stacking, which is disabled in VisiLogic. I can’t say that this is a bad thing, I think it makes the graphics much cleaner from the programming side, I just see it as a creative constraint. It’s all intuitive once you adjust, and I like the way things look afterwards, although it is generally a dated platform and lacks time saving functionalities.

Briefly – VisiLogic is extremely cost effective, great for most small jobs.

UniLogic – I’m going to cover features of UniLogic that are not included in VisiLogic. It’s their upgraded and most up-to-date platform. Apart from the list below I took from somewhere on their website, UniLogic has a WebServer for developing web pages within the HMI side of the PLC. It offers C programming for writing functions blocks to have on all your projects. UniLogic also allows communicating with the SQL database and querying it via IP address. This is one of the coolest features in my opinion, because it makes the bridge to IT more accessible than most platforms, and cost-free.

Data Tags

UniLogic is based on lexical data tags, not operands. The memory is dynamically allocated depending on the data tags you create, and the data type you link to your tags.

Data Tag Structs

These may be:

Automatically created: UniLogic creates data tag structs automatically where necessary, such as when you configure Hardware and communications, or use timers in your program.

User-defined: You set up structs according to the needs of your program.

Communications

Via Configuration, not Ladder. For example, if your application uses MODBUS, you set the desired operations/commands and operand areas in each slave configuration. You the set the frequency of data communication in the Properties Window for each slave.

User-defined Function Blocks (UDFBs). Take any UniLogic function (which are equal to VisiLogic subroutines), define input and output data tags, and then drag the function to any point in your program.

VNC– Remote Access. You can use any VNC client to remotely access your controllers.

Customize the UniLogic interface. You can dock or unpin any window in the software. In addition, note that UniLogic will fit any PC screen without any degradation in quality. The main work window can be zoomed to suit your needs.

Overall I look forward to working with one of these. I see huge potential with IT integration and very minor capital expense.

That covers my light research on Unitronics PLCs. I hope this gives a decent overview of Unitronics, although it certainly is from a programmer’s perspective. If anyone knows hardware well I would appreciate a lengthy discussion with which to become more aware of the tradeoffs.

**********************************************************

As you can tell, Ryan did his research and wrote up an excellent post discussing lots of good information on the Unitronics PLC platform. He certainly made it easy for me to add it to the blog’s resources page and it’s a good easy and informative read.

I am always looking for guest posts on automation-related topics. If anyone is interested in writing a post or contributing any other informative material, let me know! Oh, and if you are in Florida and need a controls guy who is always learning and curious, consider contacting Ryan!

Great article!