The Automation Academy

As part of an effort to bring more students to my training facility in Lebanon, Tennessee (near Nashville), I have started a new training course that I believe is one of a kind.

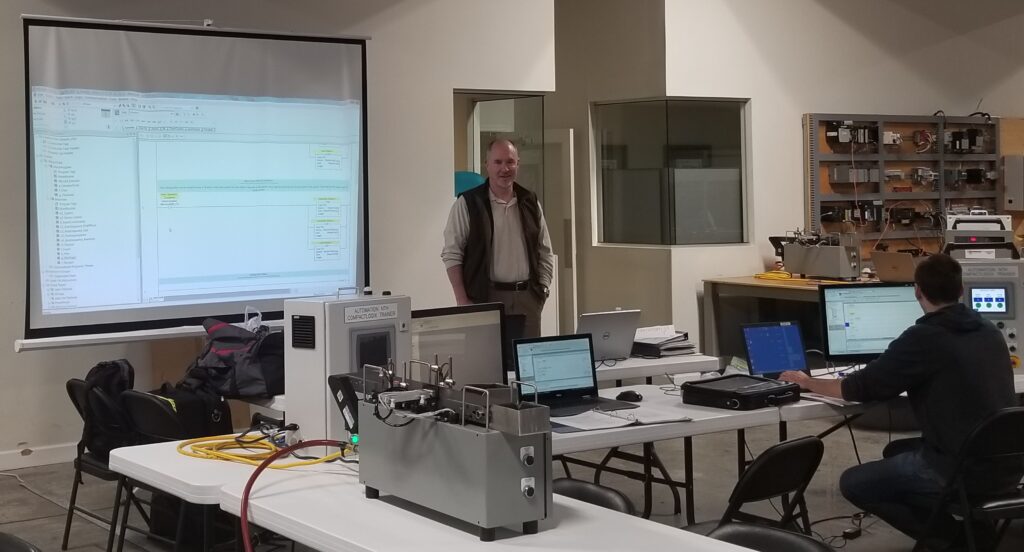

I have been teaching PLC and HMI/SCADA classes for Automation Training for about 6 years now. It gives me a chance to travel around the country and meet new people. It is an ideal situation because they own lots of PLC trainers and laptops, and ship them around North America for us.

I am the only instructor for AT that has a training facility, and they sometimes hold classes here. But I also do training for a local engineering company (systems integrator) that has an internal training program called “NTH University“. In addition to teaching their interns and new engineers, I sometimes teach their customers in a custom one week PLC/HMI/Machine Vision class.

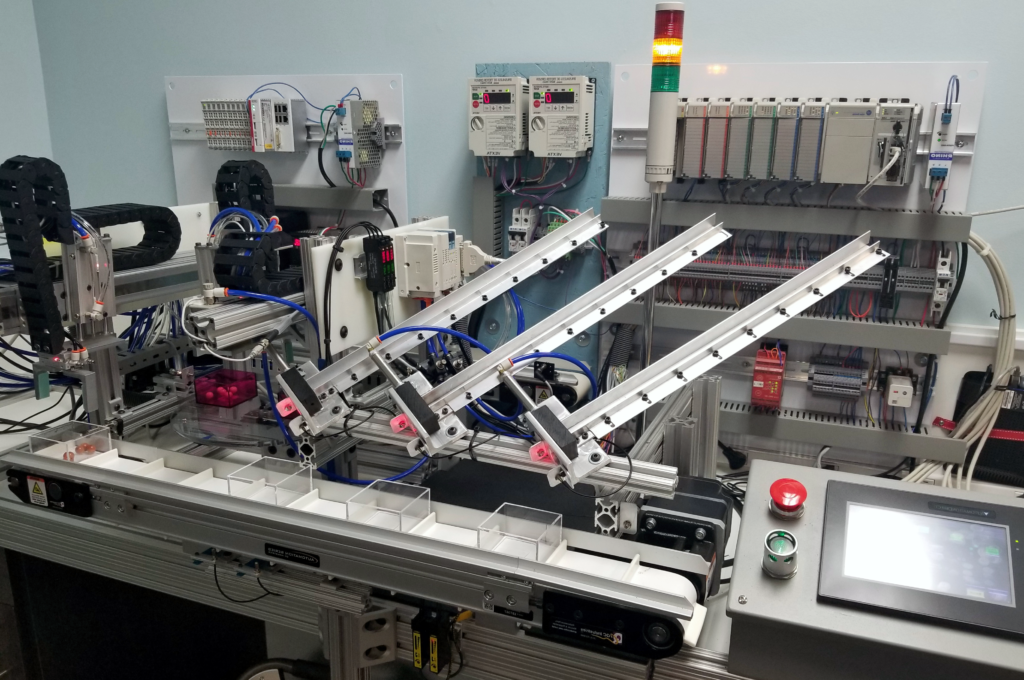

If you have followed this blog much, you will have seen my “Mini Factory”. While I originally concepted this to be used for PLC classes, I realized early on that no one was going to be able to program the whole thing in a week of class. So now I have had a couple of classes where Automation NTH engineers come here and work on the system and concentrate on different techniques, such as auto sequences, part tracking and recipes. They can combine different existing parts of the full program with a new part they want to learn.

While the Mini Factory does have a Cognex Insight camera on it, the purpose is more for integration than for machine vision training. SO for the Automation Academy classes I am building a new machine vision and troubleshooting lab.

I have a Keyence CV-X402A system with a color camera, and Cognex IS2000, IS5400 (Color) and IS 7802 smart cameras. I have been doing machine vision applications since the mid 1990s, though mostly with the old DVT brand, so I feel comfortable creating a course. The troubleshooting lab has a conveyor that will be driven both by a relay control system and a PLC, which will also be connected to the vision cameras.. There is a VFD that is wired in along with the possibility of a later safety relay with light curtain and e-stop. This will be used for electrical troubleshooting, I will sabotage the system in various ways to allow students to troubleshoot with a multimeter.

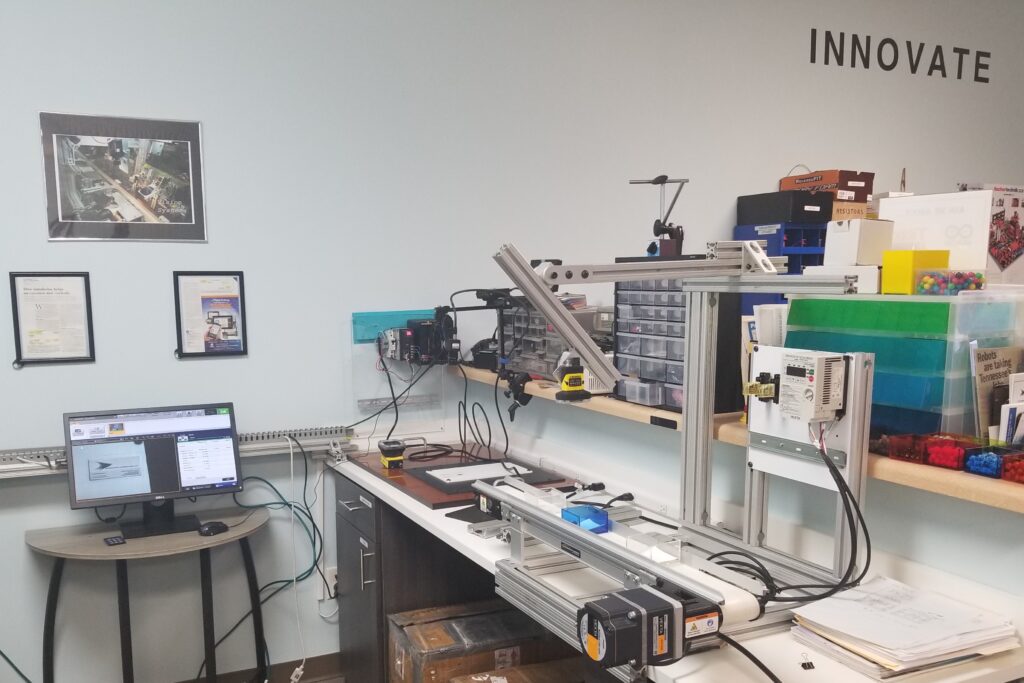

The “Innovation” lab is on the back side of the vision and troubleshooting lab. This area is for prototyping using microprocessors like Arduino and Raspberry Pi, along with building board level circuits with discrete components like resistors, capacitors, integrated circuits and bread boards. I have an oscilloscope and function generator here, as well as soldering stations and various components.

Back when all of the Radio Shacks in Nashville closed I bought a lot of their small components and kits, and really never figured out what I could do with them related to industrial automation. This bench has been a wiring and fabrication area for building my simulation trainers.

Speaking of simulation trainers, all of my small Fischertechnik simulators are also available to the Automation Academy. I have completely finished two labs for AB MicroLogix and one for CompactLogix, with another on the way.

The partially finished enclosure shown on the right in the picture above is actually the PLC controller for the Vision and Troubleshooting Lab.

Of course I also have a teaching area shown in the picture above with a projector and whiteboard.

My first Automation Academy class will be March 23-27, 2020 and will run the last week of every month. Because of Memorial Day, Thanksgiving and Christmas, the class will be a week earlier those months. I have reserved those weeks for this class for the rest of the year, 10 weeks in total.

So what will you be studying and learning? Whatever you wish! While I can handle up to eight students at a time in my facility, I only have full PLC training setups for 4-5 students, so registration will of course be limited. All of the subjects described above are available, including PLCs, Machine Vision, pneumatics, electrical troubleshooting, board level electronics, HMI programming and more. For curriculum I have both of my books (Industrial Automation: Hands On and Advanced PLC Hardware and Programming), and various other resources for machine vision and electronics. I even have an AutoCAD setup if someone wants to study that.

I have been teaching all of these subjects for a while now and have over 30 years of experience in these fields. In addition I have Lean/Six Sigma training and of course I am an Electrical Engineer with 8 years of additional electronics experience in the US Air Force, so I feel comfortable saying this is a one of a kind class that you won’t want to miss. Since this is just starting and will certainly evolve, students can sign up for one day or all five days, let me know what you want your curriculum to be ( I can send you a worksheet), and sign up for the class!

Cost is $500/person per day, my books are available at the class. First come, first serve, eventually this class may fill up pretty quick since I have limited seats.

Class Dates: March 23-27, April 20-24, May 18-22, June 22-26, July 20-24, August 24-28, September 21-25, October 26-30, November 16-20, and December 14-18. Prepaid students will have a guaranteed seat, I will fill others as they come in.

Come attend an Automation Academy class, you won’t be sorry!

How long does it take to learn automation and controls? And what is the most up to date software used in today’s industry?

Some have said that it takes 10,000 hours to become a “master” of anything. Controls consists of not only PLC programming, but CAD, knowledge of electricity, sensors and various mechanisms, HMIs and SCADA, and a host of other subjects. Unfortunately, not many of these subjects (with the exception of electricity) are taught particularly well in schools. This means you have to pick it up as you go, through jobs and whatever. Of course with this new class I am hoping to share what I have learned over the past 40 years or so with students. So if you separate all those disciplines and languages out and estimate 2000 working hours per year, do you ever really become a master or expert at any one thing? Hard to say. Good controls engineers are well rounded and know at least a little bit about a lot of different things.

About software: There is always new and updated software coming out, but you don’t necessarily want to use it. For instance, Allen-Bradley is on v32 of ControlLogix, but the version you would use needs to match the firmware revision of your controller. There is not a lot of difference in v32 and v24 of Factorytalk Studio 5000, except that the newer software supports the L80 series. Sometimes newer is better, for instance Inductive Automation’s Ignition software to me is clearly better than anything Wonderware has come out with, and certainly less expensive. TIA Portal is better than Step7 Manager for Siemens, mostly because it’s an integrated environment, and RSLogix5000 is better than RSLogix500, mostly because of the enhanced capability of the controllers themselves. So there is new software coming out all the time, there is no newest, and newer is not always better.

Looking good Frank!

Thanks Shawn, do you unfortunately see the irony in this post? Less than 2 months later a tornado wiped all of this out and then COVID-19 hit. The Automation Academy is still in my plans, but it is an entirely different thing now.