Indexers and Synchronous Machines

From The Primer:

4.2 Indexers and Synchronous Machines

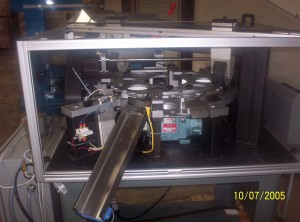

4.2.1 Rotary Cam Indexers

Rotary indexers are used to move actuators to fixed points in a circular path. They are built to move to discrete points and are typically available in 2-12 point configurations. Because they are cam driven they can be moved at a high rate of speed and handle heavy loads. They can be driven by constant speed motors and often perform other repetitive tasks as part of their operation. Camco is probably the most well known manufacturer of rotary index tables.

4.2.2 Synchronous Chassis Pallet Indexers

Synchronous chassis’ make use of a motor and line shaft to index pallets and synchronize devices performing operations around the chassis. Cams on the line shaft are used to operate devices in time with the movement of pallets. Pallet movement and dwell times are also controlled by cams. Synchronous chassis’ are more robust than systems using sensors and independent control of stations but also less flexible and more difficult to reconfigure. Indexing Drives and cam motions are specific to the machine application. Machine timing is mechanically fixed, so there is no risk of losing timing or position on individual work stations. A manufacturer that we typically use with a wide variety of configurations is Stelron.

4.2.3 Walking Beams

A walking beam uses an X and Z axis configuration to repetitively index parts a fixed distance in a single direction. The X axis moves forward with the Z axis raised carrying or pushing the part in the desired direction. The Z axis is then lowered and the X axis returned to its origin to begin another index. Walking beams are common in packaging and assembly operations because of their relatively low cost and repetitive accuracy. Axes are commonly pneumatic or servo actuated. It is pretty easy to manufacture your own walking beam since it is only two axes, though some actuator manufacturers offer them as a packaged system.

In the case of the Binder Processing machine described in the applications list previously, only one axis was driven, the horizontal one. The vertical component ended up being spring loaded clips that popped up behind the product, saving the cost of a mechanically driven axis.

here is a link on how to construct a direct drive rotary indexer without a cam

Rotary Indexer without a cam

Hello, really a nice post and thanks for sharing all about rotary index table and many other products, check this out and hope its useful.

Thank you