An HMI application

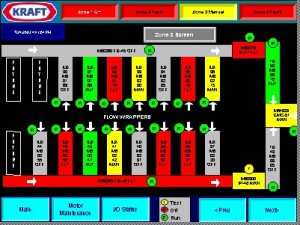

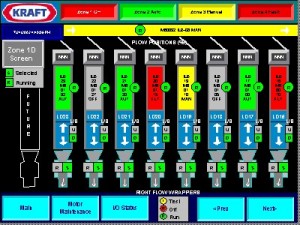

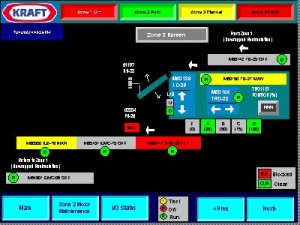

This is a screen shot from a job I subcontracted for in about 2002 or so. A Kraft Life Savers plant was shut down in Michigan due to the US tariffs on sugar and moved to Montreal in Canada. This particular line took Wintergreen Life Saver candies in bulk and divided them up into various packaging systems.

Smalley Manufacturing, a large food-service conveyor manufacturer and integrator in Knoxville, Tennessee got the material handling portion of the job. They build some very unique conveying equipment, items such as a “StorVeyor” that buffers product if the upstream equipment goes down, variable speed shaker tables and every kind of standard belt or trough conveyor imagineable were used in this system.

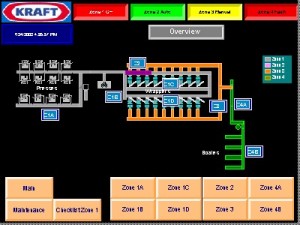

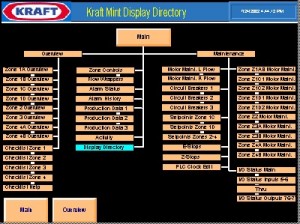

To a large extent they allowed me free rein on screen design. The end user had some specific requirements (such as French language screens and some indicator colors) but otherwise simply wanted access to any status information available. Because this system was so large I had to divide the conveyors into zones and then further into sub-zones or cells. There were 169 different conveyors, shakers or other transport devices on the system and every one had to display its own status.

Finding the screen you needed was fairly easy with both a menu or directory screen as well as simply touching the area of the screen you wanted to “drill down” into.

Overall a total blast from the creativity side. Often customers restrict what you can do to the point of it becoming a formula, but not in this case. Montreal wasn’t bad either!