Spotlight on Vision

Despite the different methods of programming and systemizing the cameras and the varying sizes of objects to be inspected, the techniques used for most of the applications were similar. Translation tools were almost always used to locate the part, the resolution of the camera vs. the target was always at least 10x what would be required, and lighting was of paramount importance. It almost always took twice as long to debug the systems as the time we had allotted also. There was generally more support required after the installation too. This simply serves to emphasize the point I would like to make here: If your firm is planning to use an integrator to implement your vision application, ensure that they have many years of practical experience. Get references from customers they have installed multiple systems for and ask them about the applications that didn’t go so well also, and there will always be some of those.

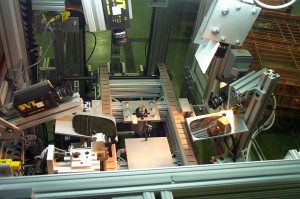

The picture above illustrates one of several technigues that can be used that don’t involve the camera or the lighting, in this case the use of mirrors. This can multiply the camera angles though the image will generally be smaller, in addition parallax issues can make measurement difficult. A previous post described the use of ultraviolet ink in an application as well as proper use of napkins and happy hour.

Don’t be afraid to think outside the box!

Good post; I totally agree that lighting is critical.

I have a love/hate relationship with machine vision; it’s really cool, but does always seem to require a lot of fiddling. You can improve performance for some parts, but be careful: you could be degrading performance for others.

One plus of smart cameras is that typically they’re a lot easier for the end user to maintain, since they always come with the development environment (unlike, say, Matrox MIL) and the development environment is typically designed for ease of use, not maximum power (unlike most PC based machine vision software).

So that’s another factor to consider: if the machine vision system is going to require occasional on-going tweaking, who will do it? If it’s the integrator, what will that cost? If it’s the user, does the user have people who can understand and tweak the vision parameters?

I’d also recommend thinking about machine vision requirements up front, instead of at the end. One job we did really would have benefited from UV visible adhesive, but the adhesive had already been chosen, and there was no way we could get them to change…

Another factor that shouldn’t be overlooked is lensing… any good vision integrator should have a variety of lenses at their disposal for testing. Maximum use of the FOV, concentric lenses for accurate gauging of components and the abilty to locate the camera at varying distances are all critical to the success of an application. Often end users and vendors don’t have the variety of lensing and lighting that a vision specialist may have and the installation suffers for it.

Automatika, that’s very true. I’ll add that I recommend the integrator and/or end user talking to (and, if possible, sending samples to) app engineers at both machine vision lens companies AND machine vision lighting companies.

Oh, yes, and mechanical constraints make life difficult; I’ve been constrained in my choice of ring lights and cameras by mechanical design considerations.

Pretty awesome blog post. About “Spotlight on Vision” whatever you wrote here is really informative. I’ve also found here an awesome conversation between Tony and Automatika about this issue. Thanks dude 🙂